Occupational Safety & Health

Basic Concept

Recognizing that the occurrence of occupational accidents has a significant impact on the survival of a company, the entire group conducts business activities with "respect for human life" as the first priority. In particular, in our production divisions, we naturally place the highest priority on safety, and we are developing various occupational accident prevention activities to cultivate a "sense of safety”. In addition, since the key to preventing industrial accidents is to develop safety-sensitive personnel, we invite outside instructors with extremely high expertise in specific fields, such as labor and social security attorneys and occupational safety consultants, to conduct training and continually reinforce learning among our employees. These efforts also cover employees of contractors.

At the beginning of each fiscal year, Yamato Steel formulates a health and safety management plan for the year, and from the perspective of preventing the company from becoming stuck in a rut, each time we present activities that we will focus on to prevent occupational accidents. We always go back to the starting point of "safety first," and the entire company, including subcontractors, is committed to the thorough implementation of 5S ("Seiri" - organizing, "Seiton" - tidying, "Seiso" - cleaning, "Seiketsu" – sanitation and "Shitsuke" - discipline), which is the basis of safety, as well as complying with basic safety rules. We are also working to identify and improve hazardous areas and dangerous work by using risk assessment and KYT (hazard prediction training). To create a safe and secure workplace, we will continue to engage in health and safety activities with the belief that "safety takes precedence over everything else".

Yamato Steel Co., Ltd. FY2025 Health and Safety Management Plan (April 1, 2025, to March 31, 2026)

Yamato Steel Health and Safety Policy

1. “Safety First”: Safety takes the highest priority in all business activities, aiming to prevent occupational accidents and ensure a safe and healthy working environment.

2. Field-driven Safety Activities: Promoting workplace-centered safety initiatives through YSQ activities※1, emphasizing ownership by workers.

3. Communication-based Safety Management: Recognizing that health and safety are built on open communication, ensuring respectful dialogue with workers on the ground.

4. Risk Assessment and Hazard Elimination: Actively utilizing near-miss reports and implementing appropriate risk assessments to prioritize and execute preventive measures.

5. Compliance and Standards: Adhering to all relevant laws and regulations, and establishing internal standards to enhance safety management levels.

6. Proactive Prevention: Sharing information company-wide to prevent the recurrence of incidents and foster a sense of ownership ("It's my responsibility") among all employees, and work toward the elimination of workplace accidents―without relying solely on reactive measures for individual cases.

7. Self-care and Health Maintenance: Encouraging individual responsibility for personal health and well-being.

<Action Goals>

-

【Safety】

- Ensure 80%+ of high-risk tasks (Risk Level III or above) receive fundamental or engineering control measures.

- Achieve 90%+ feedback incorporation rate from near-miss reports into risk assessments.

- Conduct VR-based experiential training for 50% or more of employees working in operational departments.

- Promote re-examination and monitor participation rates (all eligible employees)

- Provide health information, plan and conduct seminars, and promote awareness of the health management office (at least once a month)

- Ensure full identification of all newly handled chemical substances (obtain SDS)

- Conduct disaster response drills tailored to various disasters (fire, earthquake, tsunami, etc.) , including those based on the Nankai Trough earthquake scenario (5 times or more per year)

- Challenge to achieve zero commuting accidents and zero workplace traffic accidents

- ① 180 consecutive days without accidents

- ② Total number of accidents (including accidents resulting in no days off and accidents resulting in less than 4 days off) : 7 or fewer cases.

- ③ Number of accidents resulting in 4 or more days off: 0 cases

- ④ Number of heatstroke-related accidents: 0 cases

- ⑤ Rate of employees undergoing follow-up examinations after regular health checkups 70% or higher (※67% in fiscal year 2022, no data available for fiscal years 2023 and 2024)

- ✔ Set safety goals for each YSQ※1 team activity and promote health and safety activities led by on-site personnel.

- ✔ Introduce a new e-learning system to provide educational opportunities for all employees.

- ✔ Assign dedicated safety specialists to operational departments to improve hazard identification and prevention of unsafe behavior.

- ✔ Establish a health management office and health consultation desk to enhance industrial health activities.

【Health】

【Disaster Prevention】Enhance fire and disaster prevention awareness

【Traffic Safety】Compliance with traffic rules and improvement of manners

<Performance Targets>

<New Initiatives for Fiscal Year 2025>

※1 YSQ activities: Activities related to safety and quality (Yamato Safety Quality)

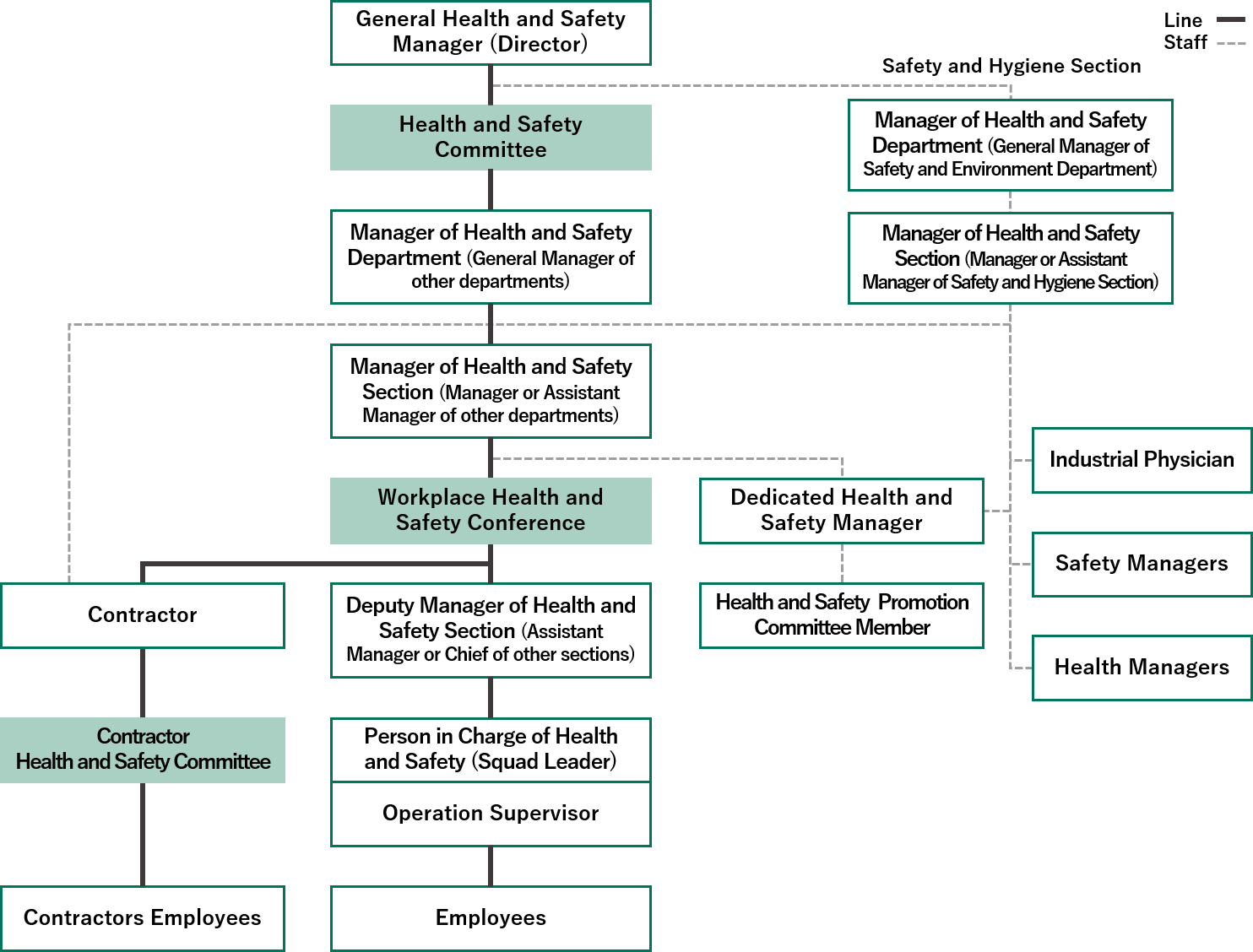

Structure

Yamato Steel has established the Health and Safety Committee and the Workplace Health and Safety Conference to promote health and safety management. The Health and Safety Policy applies not only to our company but also to our affiliated contractors, and we implement health and safety activities in cooperation with our manufacturing divisions and contractors.

Yamato Steel Health and Safety Management Organization Chart

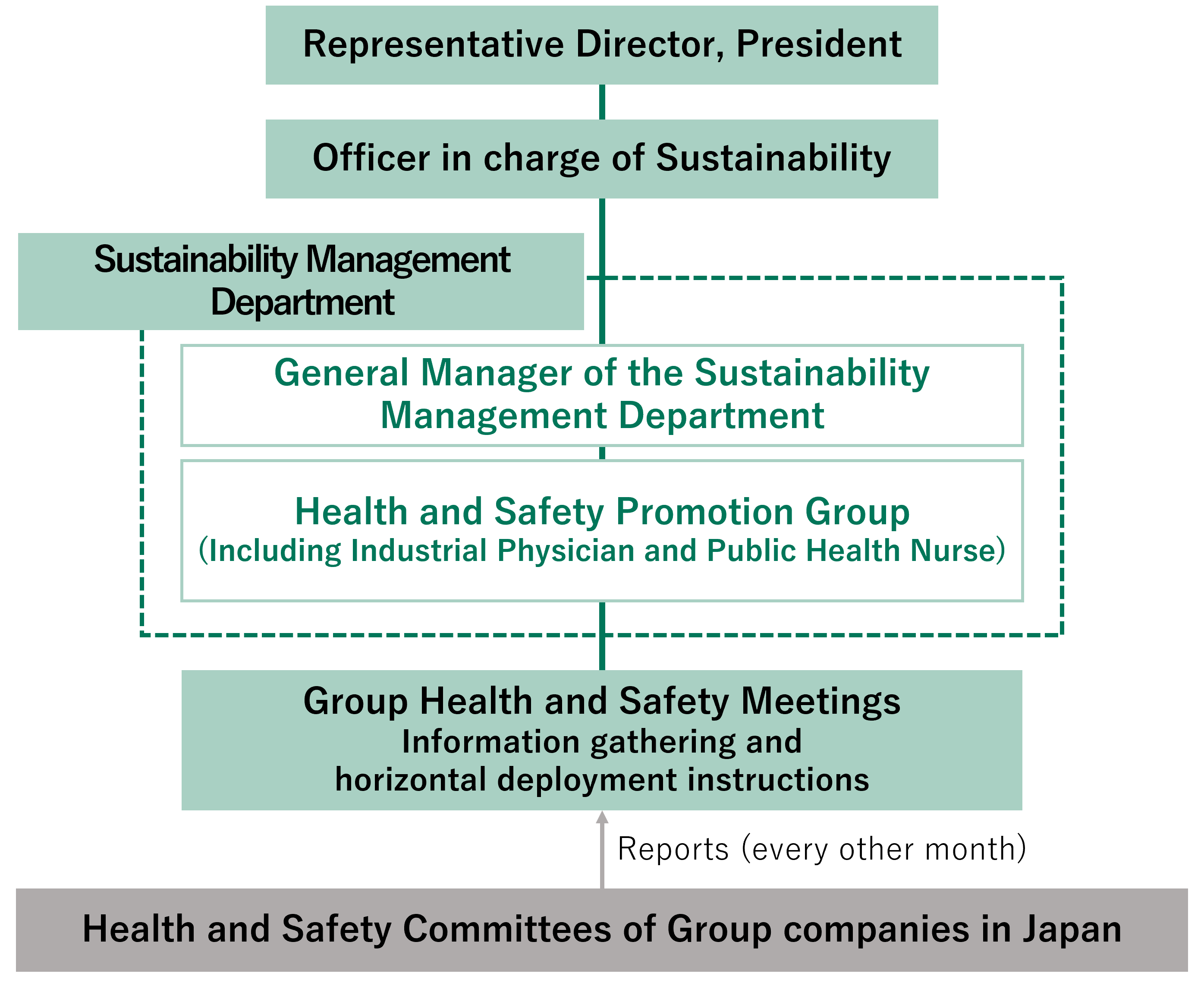

In January 2025, Yamato Kogyo has established a new Health and Safety Promotion Group as a central organization for health and safety management, with the goal of further improving safety at its business sites in Japan. Having designated 2025 as “the first year of the era of safety,” we will work closely with operational departments to promote the standardization of control standards, enhance checking systems, and promote other initiatives. Each group company has established its own Health and Safety Committee and is actively engaged in health and safety initiatives. The status of these activities is regularly reported at the Group Health and Safety Meetings, where best practices are shared across the entire Group. These matters are also reported to the Management Committee.

Yamato Kogyo Health and Safety Management Organization Chart

Prevention of Occupational Accidents

To eliminate occupational accidents, our Group has established a management organization system according to the Industrial Safety and Health Act. We also conduct risk assessments through health patrols and other types of patrols, improve workplace risks, and measure the working environment to prevent occupational accidents and illnesses among employees. To ensure safety at work in our factories, we lend safety shoes, work clothes, and all other items necessary for safe work, and AEDs (automated external defibrillators) are installed at each location.

Concerning the prevention of overwork, the attendance management system was changed in April 2024 to comply with the relevant laws and regulations (Labor Standards Act and Industrial Safety and Health Act), as well as to strengthen labor compliance and accommodate diverse work styles.

In addition, we are working to build a comfortable workplace by conducting health checkups (every April) to protect the physical health of our employees and interviewing industrial physicians in case of physical or mental weakness.

Occupational Accident Prevention Activities

Priority Action Items: Initiatives and Achievements in FY2024(PDF:359KB)

Priority Action Items: Targets for FY2025(PDF:456KB)

Mental Health Care

In the health and safety management plan formulated at the beginning of each fiscal year, we set a plan for mental health care as one of the priority items to be implemented and introduced a stress check system for all employees to prevent mental health problems by helping employees recognize and cope with their stress and improving the work environment. We have introduced a stress check system for all employees.