Introduction to Businesses and Products

The Lives and Future

That We Support

Through its steel, heavy industry, and trackwork materials businesses, the Yamato Kogyo Group supports social infrastructure that is essential for people’s lives.

Through our contributions to infrastructure not only in Japan but in a variety of other countries and regions, we make a significant contribution to developing the future of the planet.

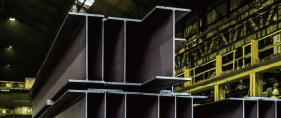

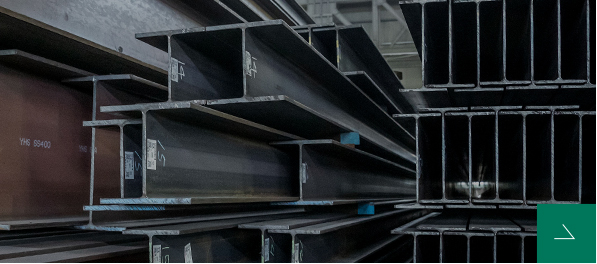

Steel

Our steel business consists of two departments: "steel making" and "rolling".

In the steel making department, semi-finished products are made using a large electric arc furnace and continuous casting machine. Then, in the rolling department, the semi-finished products are processed and formed into various types of products by machinery such as a reheating furnace and rolling mill.

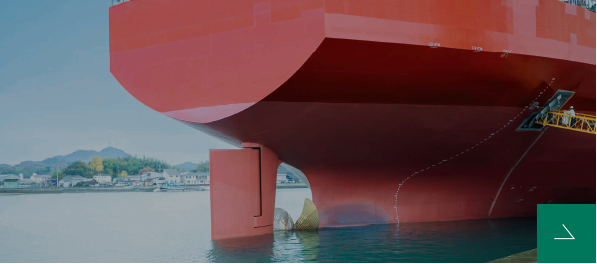

Heavy Industry

The Heavy Industry businesses is focused on the stern frames that support the rudder and propellers on the sterns of ships. As a stern frame manufacturer, it has one of the highest market shares in Japan.

A major strength is that it has an integrated production line that can manufacture everything from large castings, to machined parts, to large structural steel components.

Trackwork

Materials

The trackwork materials business makes wide-ranging contributions to the safety of railways through its turnouts, anti-derailing/deviation guards and other products.

This is the business on which Yamato Kogyo was founded, and the technology and experience that we have accumulated over the course of more than half a century are highly rated and trusted by customers both in Japan and overseas.

Product information for

Yamato Trackwork System Co., Ltd.

*Japanese version only

Manufacturing locations

Yamato Kogyo is a global company that has expanded its business all over the world from Himeji City, Hyogo prefecture.

The employees of the Group are working together as one to provide comprehensive local support for the local manufacture and sale of steel products, and to provide manufacturing that supports social infrastructure around the world.

Products at Overseas Locations

-

Jumbo H-Beams

Jumbo H-beams are heavy wide-flange structural shapes with a weight per foot up to 808 pounds and a flange thickness exceeding 5-inches.. These heavy shapes are used in columns and trusses in high-rise building construction, stadiums, and other applications.

-

Z Sheet Piles

Z-shaped sheet piles are called Zs because the single piles are shaped roughly like a horizontally stretched Z. Steel sheet piles are long structural sections with a vertical interlocking system that create a continuous wall. The walls are often used to retain either soil or water. The ability of a sheet pile section to perform is dependent upon its geometry and the soils it is driven into. The pile transfers pressure from the high side of the wall to the soil in front of the wall. Z piles can be used in a wide variety of applications such as retaining walls, cofferdams, parking garages, environmental barrier walls and steel bulkhead walls.

-

Rebars

Reinforcing bar is defined as bar steel which is used to reinforce concrete on Korean Standards.

It is widely used at building construction and civil engineering sites now that it has the advantages of serving as key building materials for a bridge, building, nuclear power plant etc. Today, plus reducing the width of concrete cracks when they occur.

Reinforcing bar is manufactured by hot rolling, and divided into steel round and steel deformed according to the cross-section type, YKS produces steel deformed. -

Angles

Angles are used for making transmission towers required for power and communication applications. Angles are a crucial component in ensuring a safe and reliable structure for the towers.

Towers transmit power, communication and radio waves, which is an essential component to any aspiring community. The efficiency and accuracy of towers is greatly improved with the production and use of angles.

※Yamato Steel does not handle these products.

What are H-Beams?

As the name suggests, H-beams are pieces of steel material that have the shape of the letter “H” in cross section, and are primarily used in major structures such as buildings, factories, stadia, and shopping malls, and in the piles that support them.

H-beams consist mainly of the central vertical portion, called the web, and the horizontal parts on either side, called the flanges. This shape is instrumental in supporting the significant loads imposed by structures.

The Company also manufactures “hi-spec H-beams” whose chemical composition exceeds that of JIS standards.

What are Sheet Piles?

Sheet piles are steel materials used for such purposes as stabilizing foundations and preventing water ingress.

These are used mainly for civil engineering projects, with each pile driven into the ground on sites where construction is scheduled and interlocked by means of protrusions at the ends.

Constructing steel walls of this kind protects against water pressure and soil pressure, and also prevents leakage or flows in and out of sand, groundwater, seawater, and other substances.

They are used to strengthen weak soil and unstable foundations, to reinforce building foundation structures, to provide a means of preventing landslides on sloping sites, and to protect river banks and coasts.

What are Stern Frames?

Stern frames are components that are essential for the propulsion of vessels, and are incorporated into the sterns of large ships such as tankers and containerships to support the rudder and propellers.

The manufacture of stern frames requires a high degree of precision and technological capability. The Company uses its know-how in three-dimensional bending, cast products, and other manufacturing technologies to contribute to shipbuilding.

What is Rolled Steel for Shipbuilding?

Rolled steel for shipbuilding (unequal angle/thickness steel) refers to shaped steel products that are used in the construction of ships. They are used as frames for shipbuilding. They are also referred to as NAB or inverted angles.

In addition to ships, they are used for large structures such as bridges and tanks.

What is a Turnout?

A turnout is a piece of equipment located before the station that decides the direction a train will take as it moves forward, and without which a railway could not function. The PC sleeper turnouts made from concrete that replaced the previous wooden sleepers not only reduce maintenance and have longer lifespans, but also help preserve forestry resources.

What are Anti-Derailing/Deviation Guards?

[Anti-Derailing Guards]

These are protective devices installed on the inner surfaces of the rails to prevent the wheels of a bullet train from leaving the rails and derailing in the event of an earthquake.

[Anti-Deviation Guards]

These are protective devices installed to ensure that, even in the event of a bullet train being derailed, the train does not collide violently with other trains, tunnels, or station facilities.