Top Message

Toward the realization of a sustainable society,

Yamato Kogyo Group will work to achieve both sustainable growth and enhance corporate value.

We will support your future.

Yamato Kogyo Co., Ltd.

President

Yamato Kogyo Group’s Vision

Yamato Kogyo was Founded in 1944, starting with manufacture and repair of trackwork materials. From the 1950s to the 1970s, Yamato Kogyo manufactured cast steel products, introduced electric furnaces and continuous casting machines, and introduced universal mill, laying the foundation for the Yamato Kogyo Group's steel and trackwork materials businesses. In the late 1980s, Yamato Kogyo was one of the first electric furnace manufacturers in Japan to expand our overseas business to the U. S., Thailand, South Korea, the Middle East, Vietnam and Indonesia.

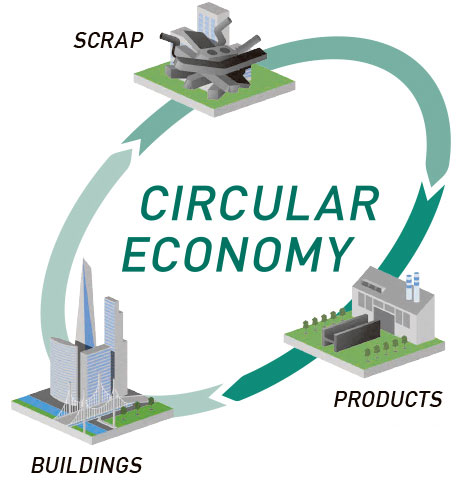

Steel is an important material that supports the foundation of society in civil engineering, construction, and railroads. In addition to its ease of processing, steel has cost advantages and will continue to be an important material that supports the world's social infrastructure. Taking advantage of steel's exceptional recyclability, we are practicing a circular economy through our recycling business, which uses steel scrap that has reached the end of its useful life as a resource and revives it into new steel products. In recent years, environmentally friendly manufacturing has been attracting attention, especially as a measure against climate change. Our electric furnace method of steel production is expected to become increasingly important in the future because it emits less CO2 than the blast furnace method.

In addition, the manufacturing of steel in electric furnaces is a process of local production for local consumption. We reuse local steel scrap, hire and train local people, and manufacture products to support the infrastructure of each country and region. Our mission is "Our Steel, Your Future.” By contributing to the development of social infrastructure in a way that is deeply rooted in the local community, the steel we make will help realize the development and prosperity of each country and region and lead to the future of the people. We will continue to support the development of society and contribute to the realization of a sustainable society through environmentally-friendly steel manufacturing.

Formulation of Six Materialities and Medium-term Sustainability Plan

We consider sustainability management to be the sustainable growth of a company while maintaining the environment and society as the foundation of our business. In addition to sustainable growth through business activities, we recognize the impact our group has on the environment and society, and we are committed to working together as a group to solve social issues by integrating social fairness, contribution to local communities, and consideration for the environment into its management. We contribute to society by providing safe and high-quality products, and as an important player in the circular economy, we conduct our business activities with an emphasis on environmental conservation.

To promote sustainability management, under the CSR Committee (currently the Sustainability Committee) established in August 2020, we have identified themes (materialities) that we consider highly important for ourselves and our stakeholders and formulated the Medium-term Sustainability Plan targeting fiscal 2025. Our Group will focus on the following six materialities: 1. Climate change, 2. Resource recycling, 3. Eco-friendly products, 4. Product liabilities, 5. Human resource development, and 6. Corporate management base. We will steadily promote activities from a medium-term perspective based on the six materialities. To ensure the sustainable growth of the Group and to enhance our social value as a company, we will work to raise awareness and spread awareness throughout the Group under the Sustainability Committee, focus more on what we have been doing, and actively communicate our efforts.

Tackling Climate Change Issues through Energy Conservation & Production Rationalization

As a steel manufacturer, dealing with environmental and climate change issues is one of the most important themes for our group. As a manufacturer of electric furnaces, our group has supported the economy through resource recycling, a method of creating steel by reusing steel scraps over and over again. In addition, our group is promoting energy conservation and rationalization of production, and practicing the reduction of CO2 emissions. Electric furnaces use a lot of electricity, so the CO2 emission figures are greatly affected by changes in the power supply structure of electric power companies. However, by introducing streamlined equipment such as a single-stage preheater, our Group can produce products with about one-sixth the CO2 emissions of blast furnace manufacturers and more than 25% fewer CO2 emissions than general electric furnace manufacturers.

In a world where consideration for the environment and sustainability are important, we believe that steel manufacturing using electric furnaces will become even more important in the future. In light of this situation, to further accelerate our decarbonization efforts, we have formulated the “Domestic 2030・2050 Environmental Vision," which aims to become carbon neutral by 2050 and to achieve a 46% reduction in CO2 emissions by 2030 compared to the fiscal 2013 level. In the Medium-term Sustainability Plan, we are targeting a 38% reduction in CO2 emissions by 2025 compared to the fiscal 2013 level, and we are steadily working to reduce CO2 emissions by accumulating various energy-saving and other measures in our own company.

In addition, Yamato Steel Co., Ltd., a group company, has acquired certification for the EcoLeaf and Carbon Footprint of Products (CFP) environmental declarations for its six main products. It is the first company in the domestic steel industry to acquire these two types of certifications. As the global trend toward decarbonization accelerates, we hope that our customers will appreciate our environmentally friendly products and specify them as steel products for civil engineering and construction.

We are also working to address environmental and climate change issues on our overseas bases, Siam Yamato Steel Co., Ltd. (SYS), a consolidated subsidiary in Thailand, is engaged in solar power generation and waste heat utilization and plans to expand its 5.6-megawatt solar power generation facility by another 1.6 megawatts in fiscal 2024. In addition, the company is also considering the introduction of floatovoltaics (floating solar power generation) in cooperation with Rayong Province, where it has its base. We intend to share such advanced overseas initiatives and information with the entire group to address climate change issues and enhance our corporate value.

Our Group will continue to achieve both a sustainable society and sustainable growth and enhancement of corporate value under the mission of "Our Steel, Your Future". We look forward to the continued guidance and encouragement of all our stakeholders.