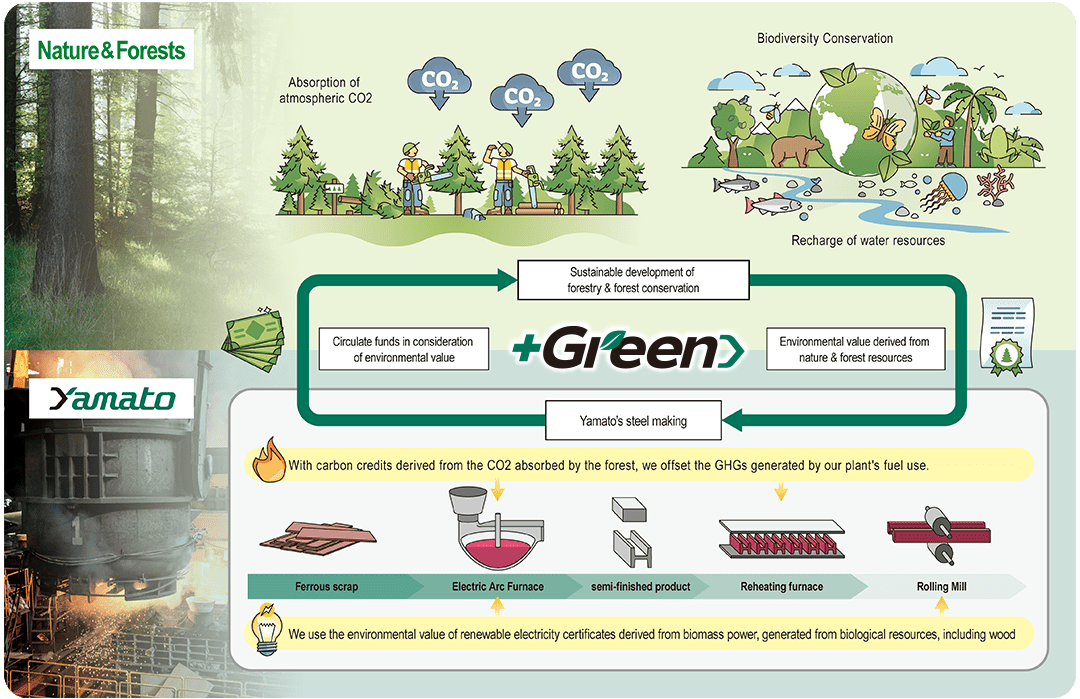

+Green is carbon offset steel product of Yamato Steel Co., Ltd.

with environmental value derived from nature and forests.

Reasons to support nature and forest resources

Ratio of Japan's land covered by forests

![]()

![]()

The forest coverage of Japan is approximately 70%, and 40% of this is planted forest.

Planted forests require systematic care and if properly managed, they can retain water resources as well as natural forests and provide a habitat for a variety of living things such as animals, birds, insects, and fish.

The steel industry uses large amount of water. We can say that our industry has been supported by the water resources derived from forests.

Percentage of forestry in domestic GDP

![]()

![]()

Japan's forestry industry is facing challenges such as aging workforce as well as declining income due to the high competition with foreign timbers. As a result, an increasing number of forests are becoming difficult to manage unlike the past.

With a sense of urgency that forests will be lost as a precious natural resource if nothing is done, efforts to realize sustainable forestry have been attracting attention in recent years.

GHG reduction potential of forests in Japan's NDCs

![]()

![]()

Forests also contribute to the prevention of global warming by absorbing CO2.

In order to achieve Japan's GHG reduction target, CO2 absorption by forests is expected to account for about 6% of the total reduction.

However, in forests that are not well maintained, sunlight cannot reach the forest floor because of dense older trees.

As a result, young trees with excellent CO2 absorption capacity do not grow well because they lack the sunlight necessary for growth.

Percentage of the steel industry emmisions in Japan's total CO2 emissions

![]()

![]()

The steel industry is closely related to the global environment not only in terms of GHG emissions, but also energy and water use.

Our +Green aims to contribute to the sustainable development of the domestic forestry and the decarbonization of society through circulation of funds via environmental value.

What +Green can offer

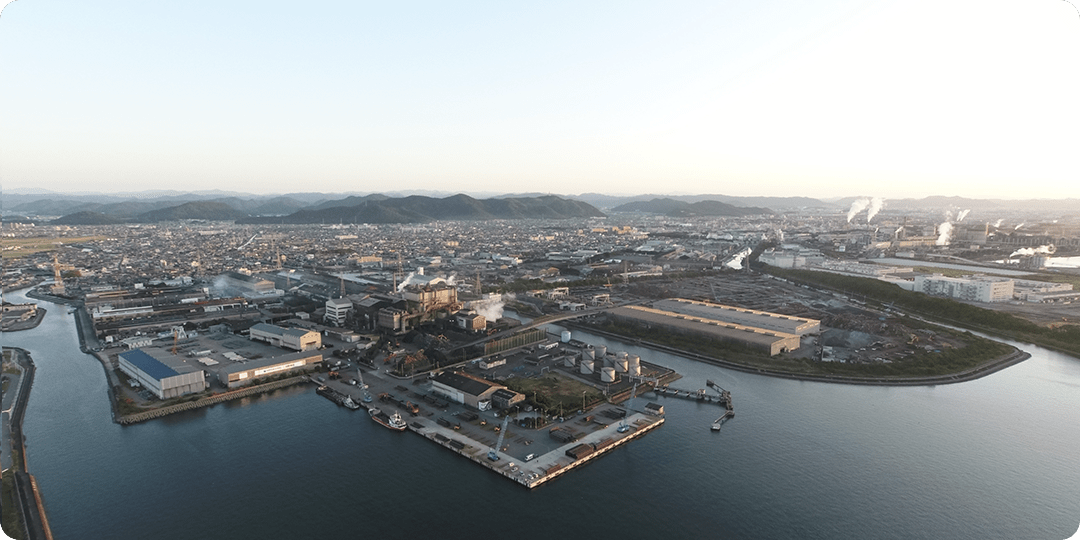

Electric Arc Furnace steel products with 60 years of pursuit of energy conservation and rationalization

Ever since our first Electric Arc Furnace went into operation on October 12, 1956, we have been pursuing quality improvement, energy conservation, and rationalization. As a result, our greenhouse gas (GHG) emissions from production have been reduced to one of the best in Japan.

This is the result of our company’s history of operational rationalization, energy conservation, fuel conversion, and pursuit of optimal equipment and manufacturing processes tailored to the characteristics of each product.

In addition, in the “Domestic 2030/2050 Environmental Vision” announced in 2023, Yamato Kogyo Group initiated its challenge to become carbon neutral by 2050 and aims to reduce CO2 emissions in 2030 by 46% from the 2013.

+Green can be supplied for all Yamato Steel products.

Ingot production in the first introduced Electric Arc Furnace

Current beam blank (semi-finished product) manufacturing process

Installation of Industry's first Single Stage Preheater: SSP

Trial and error among employees to constantly strive for the best operation

Offsetting GHG emissions through environmental values derived from natural and forest resources

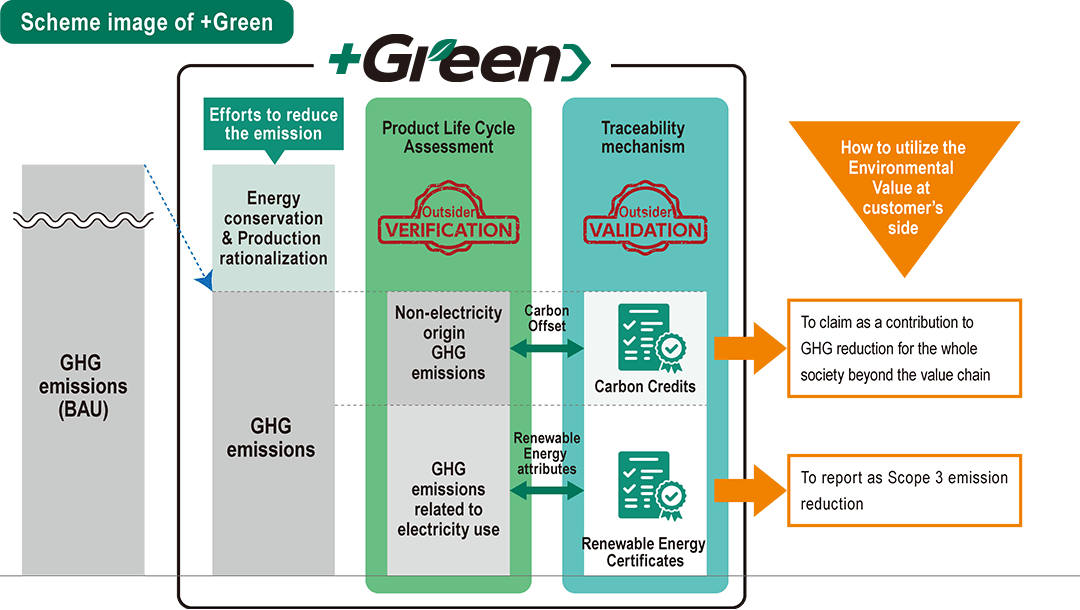

+Green is our steel product that we have offset the residual GHG emissions that cannot be reduced through our own efforts with forest-derived carbon credits and Renewable Energy Certificates of biomass power generation.

Information on the GHG emissions and the environmental value used to offset the GHG emissions of our products will be listed on the “+Green Certificate” that we issue and provided with our customers.

Customers who purchase +Green can also utilize the environmental value of this product in the following ways.

The value that +Green aims for

A properly managed forest is an irreplaceable resource that absorbs CO2 from the atmosphere and plays an important role in preserving biodiversity.

We are committed to the sustainable development of nature and forest resources by engaging only forest and biomass-based carbon credits and renewable energy certificates applied for +Green, and by circulating the funds in return to those who are involved in forest conservation activities.

Together with our customers who purchase +Green products, we also would like to contribute to GHG reduction in the whole society, beyond the value chain.

Verification and Validation

by third-party

Yamato Steel's +Green has received third-party verification from the Sustainable Management Promotion Organization (SuMPO) in accordance with ISO 14025 on the environmental impact (GHG emissions) of raw material procurement and production, calculated using LCA methods in accordance with ISO 14040 and ISO 14044.

In addition, we have received validation from DNV Business Assurance Japan regarding Appropriateness of the traceability management of credits and renewable energy certificates through external procurement and the issuance system of independent certificates in accordance with the internal standards of third-party verification organizations in support of ISO 22095:2020 and the internationally recognized Chain of Custody standard.

For more information on Yamato Steel's EPD (LCA Verification Report) for steel products, please refer to the website of the Environmental Labeling Program operated by the Sustainable Management Promotion Organization (SuMPO).

the website of the Environmental Labeling Program operated

by the Sustainable Management Promotion Organization

For a third-party Validation Opinion, please see below. Validation Opinion

If you would like to inquire about +Green, please use the link below. Contact us(For “Type of Inquiry”, please select “Sustainability”.)