Our Steel, Your Future

ーAt a Glanceー

Realizing a Circular Economy with Steel

Sustainable Business by Leveraging the Advantages of Steel and Electric Arc Furnaces

Responsibility to the Environment

Necessary Decarbonization Initiatives for the Steel Industry

In recent years, global warming and the accompanying problem of climate change have become major issues that threaten the lives and livelihoods of people.

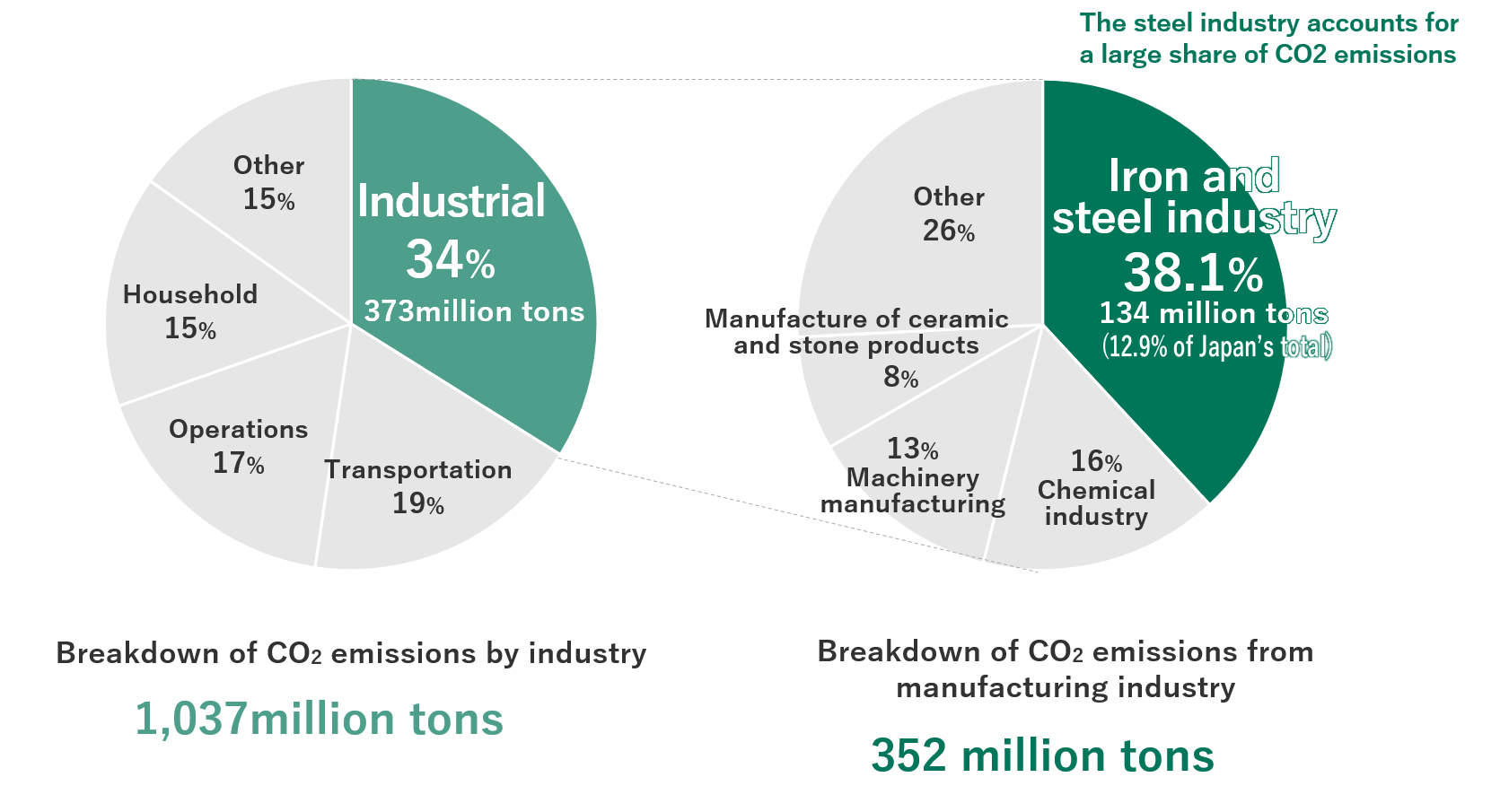

As a key industry that supports infrastructure and other aspects of Japanese society, steel has played an important role in the past, but at the same time the production processes need extraordinary amounts of energy. Because the steel sector accounts for 12.9% of CO2 emitted in Japan, the highest of any industry, we recognize that the role that we are required to play going forward will be exceptionally important.

The Yamato Kogyo Group is approaching this issue with the utmost seriousness, and we will contribute to realize a sustainable society by enhancing its technological capabilities, improving its energy efficiency, and taking other measures to proactively reduce CO2 emissions.

CO2 Emissions by Industry

(Source: Ministry of the Environment, FY2022 Greenhouse Gas Emissions)

The Strengths of Electric Arc Furnaces

The Advantages of Popularity-Gaining Electric Arc Furnace Steel Making other than Recycling

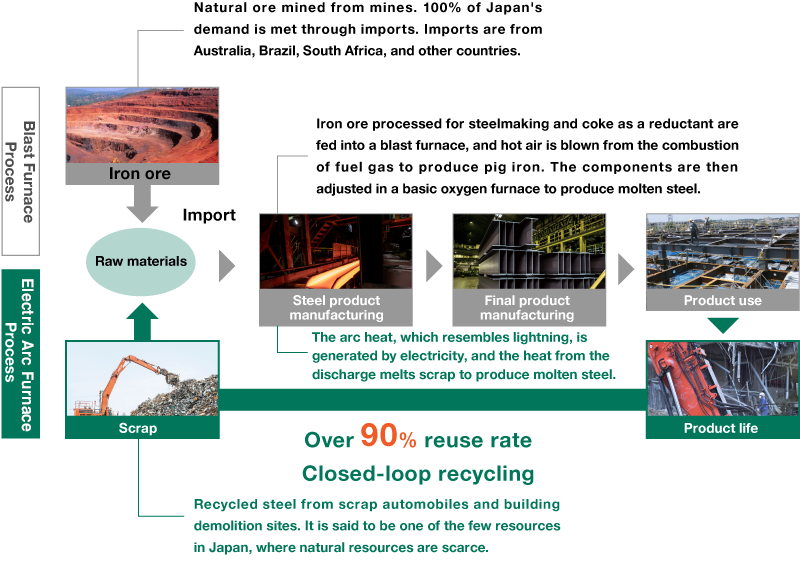

Iron not only exists in abundance in the world but is also inexpensive and easy to process, and because it has a recycling rate of more than 90% it is sometimes referred to as “the semi-permanently recyclable material.” By leveraging those characteristics to the maximum to achieve perfect recycling (closed-loop recycling), the Yamato Kogyo Group seeks to reduce both the volume of natural resources extracted and the amount of energy consumed.

Broadly speaking, the two main methods of steel production are the blast-furnace method and the electric arc furnace method.

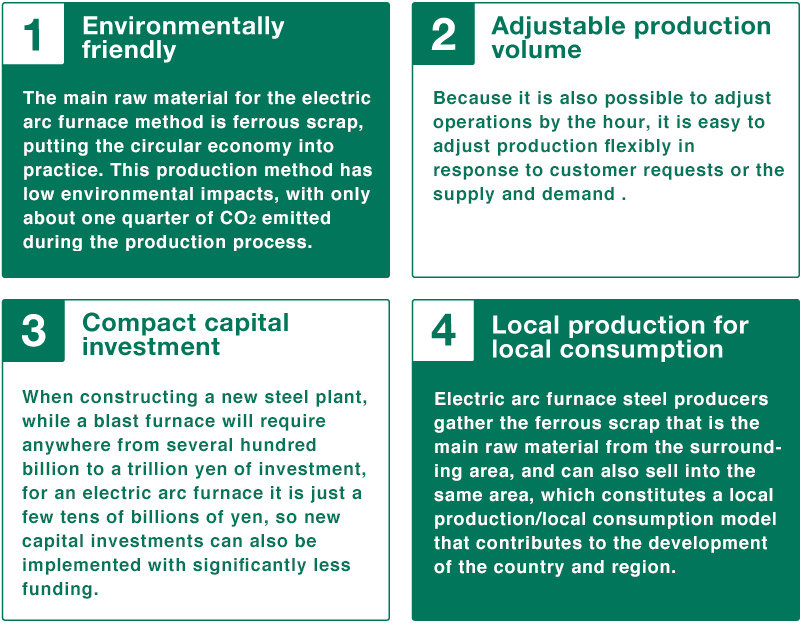

In the electric arc furnace method used by the Group, ferrous scrap is the main raw material used. By using the heat of an electric arc to melt scrap that has come to the end of its life so that it can be reborn as new steel products, we put the circular economy into practice through the recycling of resources.

The amount of CO2 emitted by melting scrap using heat generated by electricity is about one quarter of the CO2 emitted by the blast-furnace method. Moreover, it is also possible to adjust operations by the hour, such as by capitalizing on low-cost nighttime electricity, making it easy to adjust production flexibly in response to customer requests or the supply and demand.

As of 2021, the electric arc furnace method accounted for around 25% of crude steel production in Japan. In the United States the electric arc furnace ratio is around 70%, while the share of electric arc furnaces globally is approximately 30%. In recent years the share of production by the environmentally friendly electric arc furnace, with its low CO2 emissions, has been trending upwards.

Closed-loop Recycling of “Iron”

Features of the Electric Arc Furnace

Yamato Kogyo Group’s Initiatives

Always One Step Ahead as a Leading Environmental Company

Even compared to other electric arc furnace steel producers, the Yamato Kogyo Group focuses on environmental initiatives. Yamato Steel Co., Ltd., which is the core company of the Group, was the first in the industry to adopt the single stage pre-heater (SSP) in fiscal 2019, which uses the heated gas discharged by the electric arc furnace to preheat scrap, thus achieving significant energy savings and reduction of CO2 emissions.

Single stage preheater (SSP)

The Company has also introduced a regenerative burner, low-temperature rolling, operation automation, and other steps to further improve productivity. In addition, it has leveraged the strengths that enabled it to expand globally before others in the steel industry to collaborate with overseas group companies, with the objective of enhancing technological capabilities and improving energy efficiency. The Company was also the first in the domestic steel industry to obtain certification under the EcoLeaf and Carbon Footprint of Products (CFP) environmental declaration programs run by the Sustainable Management Promotion Organization.

Going forward we plan to introduce exhaust gas analyzers for electric arc furnace, and to upgrade the rolling mill in stages. Not only do we expect these efforts to reduce CO2 emissions through lower energy usage and to rationalize production, but we also anticipate improvements in customer satisfaction as a result of being able to produce even higher quality products.

Siam Yamato Steel Co., Ltd. (SYS), our Group Company in Thailand, is also proactively implementing environmental measures, such as utilizing natural energy through solar power generation and promoting the use of waste heat. Between 2017 and 2020, it installed solar power facilities with a generating capacity of 2.84 MW, which has been confirmed to cut 2,000 t-CO2 annually. In 2021, it installed an additional 2.76 MW of solar panels, taking the total renewable energy installed capacity to 5.60 MW, with plans to expand by 1.6 MW in 2024. The Company is also considering participating in the hydroelectric power generation facility construction project sponsored by Thailand’s Provincial Electricity Authority (PEA) and Industrial Estate Authority of Thailand (IEAT). In the event that this is introduced, SYS could reduce electricity purchase prices.

Solar power generation equipment installed in Thailand (SYS)

Yamato Kogyo Group’s Goals

With an Eye on Global Support

We were one of the first Japanese electric arc furnace steel producers to expand business globally and we currently operate in eight countries around the world. As a pioneer in global expansion, we have supported the infrastructure and development of each country and region through our steel products and trackwork parts businesses and have contributed to the promotion of local industries and the creation of employment by passing on technology. Our Group is also committed to fulfilling our responsibility to the global environment by taking advantage of the unique characteristics of electric arc furnace which realizes “local production for local consumption”, and by successfully integrating the know-how we have cultivated in Japan with the characteristics of each region while reducing the environmental impact of the entire product life cycle.